Published on 30 September 2019

The Institution of Engineering and Technology (IET) innovation awards recognise and celebrate the very best new innovations across the breadth of science, engineering and technology. This year the IET received over 360 entries for the innovation awards and we are delighted to announce that they have shortlisted Eva Agapaki, Laing O’Rourke Centre for Construction Engineering and Technology PhD student working in the Construction Information Technology Laboratory, in the category of "Information Technology".

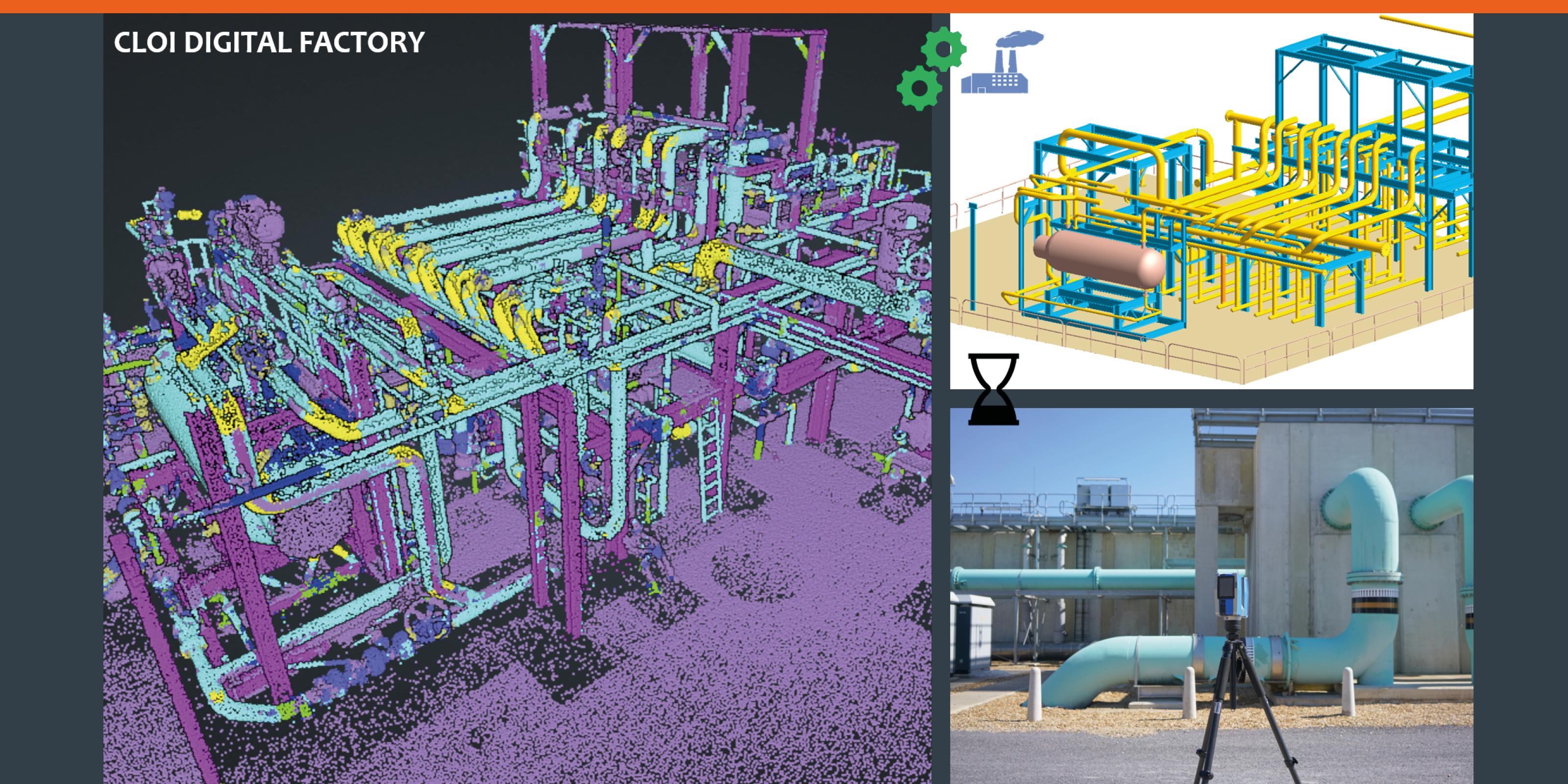

Large scale industrial facilities require frequent maintenance in order to avoid accidents that impede with production or cause environmental or other damage. To amend the large cost and inconvenience that onsite maintenance implies, one proposed solution is to develop a geometric Digital Twin (gDT) of the facility. However, costs and labor of modeling industrial factories counteract the value of gDTs. 90% of the modelling time is spent in processing real world laser scanned data, due to the complexity and the number of industrial shapes existing in these assets. As such, current conditions are not properly mapped, but also do not even have a designed model. We argue that the use of semantic (clustering by object type) and instance (clustering by individual object) layers gives contextual information that is useful for stakeholders, engineers and managers of the facility. However, these layers could not be generated so far due to the lack of large databases of richly annotated, laser-scanned industrial shapes as well as lack of appropriate inference rules in order to learn these shapes. Our CLOI innovation provides: (a) the largest richly annotated dataset of the most important industrial shapes (CLOI) that need automated modelling, (b) a procedure to intelligently parse large spaces and segment CLOI industrial shapes using deep learning networks and contextual inference rules. Our prototype takes as input spatial coordinates of laser scanned factories and for each coordinate outputs what type of object it belongs to (class), as well as which specific object instance it belongs to. Our pipeline is fully automated and readily applicable by the end user.

The winners will be announced at the Award Ceremony on 13 November at The Brewery in London.

Visit Eva’s profile for further details and contact information.

The text in this work is licensed under a Creative Commons Attribution 4.0 International License.